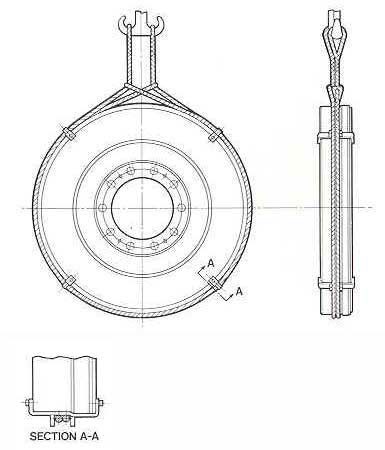

Damper Service

Condition monitoring of the damper is an essential preventative maintenance practice. This ensures the torsional vibration system of the vessel, generator or pump continues to function as per the design calculations, thus preventing early life failures. The internal condition and operating efficiency of the Holset viscous damper should be monitored by extracting small samples (1cc.) of silicone fluid for laboratory analysis removal of a silicone fluid sample is a simple process which should be initially carried out after 15,000 hours of engine operation or at the first major engine service.Metaldyne will advise subsequent sampling intervals via the analysis report. Special sampling kits complete with instructions are available from Metaldyne Int UK Ltd or an appointed service representative Metaldyne reports satisfy Survey Societies requirementsThe Metaldyne laboratory report meets all the requirements of major survey classification societies like Lloyds, ABS, DNV BV for marine propulsion and auxiliary power installations at the 5 year surveyVisit the AAM Driveline Halifax website for more information on Damper Service