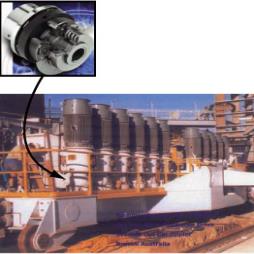

Rail Car Tipper

1. Rail Car Tipper Application: Iron Ore Rail Car Positioner Drives – Brevini Australia Function: In Australia, Iron ore is often mined hundreds of kilometers from the export ship loading facilities. The ore is shipped to the port via railway lines. The iron ore trains are the longest in the world. BHP Billton ran one train that stretched 7.4 Km, had 682 cars, eight locomotives, a gross weight of almost 100,000 tonnes and moved 82,262 tonnes of ore. When the train arrives at the export facilities, they are shunted into holding yards and the locomotives are uncoupled. The ore is removed from the rail cars by a tilting mechanism, the ore cars are picked up from the line turned over, emptied and positioned back on the rail line. The positioner machinery couples up to three ore cars and then travels slowly to the tilting mechanism, uncouples and then travels back at high speed to the couple three more ore cars. This is a continual operation unit the complete train of ore cars is emptied. The Autogard Torque Limiter is fitted to protect each drive in the case of a drive overload. Most overloads are caused by a build up of ore on the rail tracks. Torque Limiters: Model 406 size 5 SR. The torque limiters are fitted with dust covers and are balanced to operate at speeds between 24 rpm and 2000 rpm. Benefits: The torque limiter prevents damage to the drive train due to overloads. Increased productivity due to reduced downtime.Visit the British Autogard Ltd website for more information on Rail Car Tipper