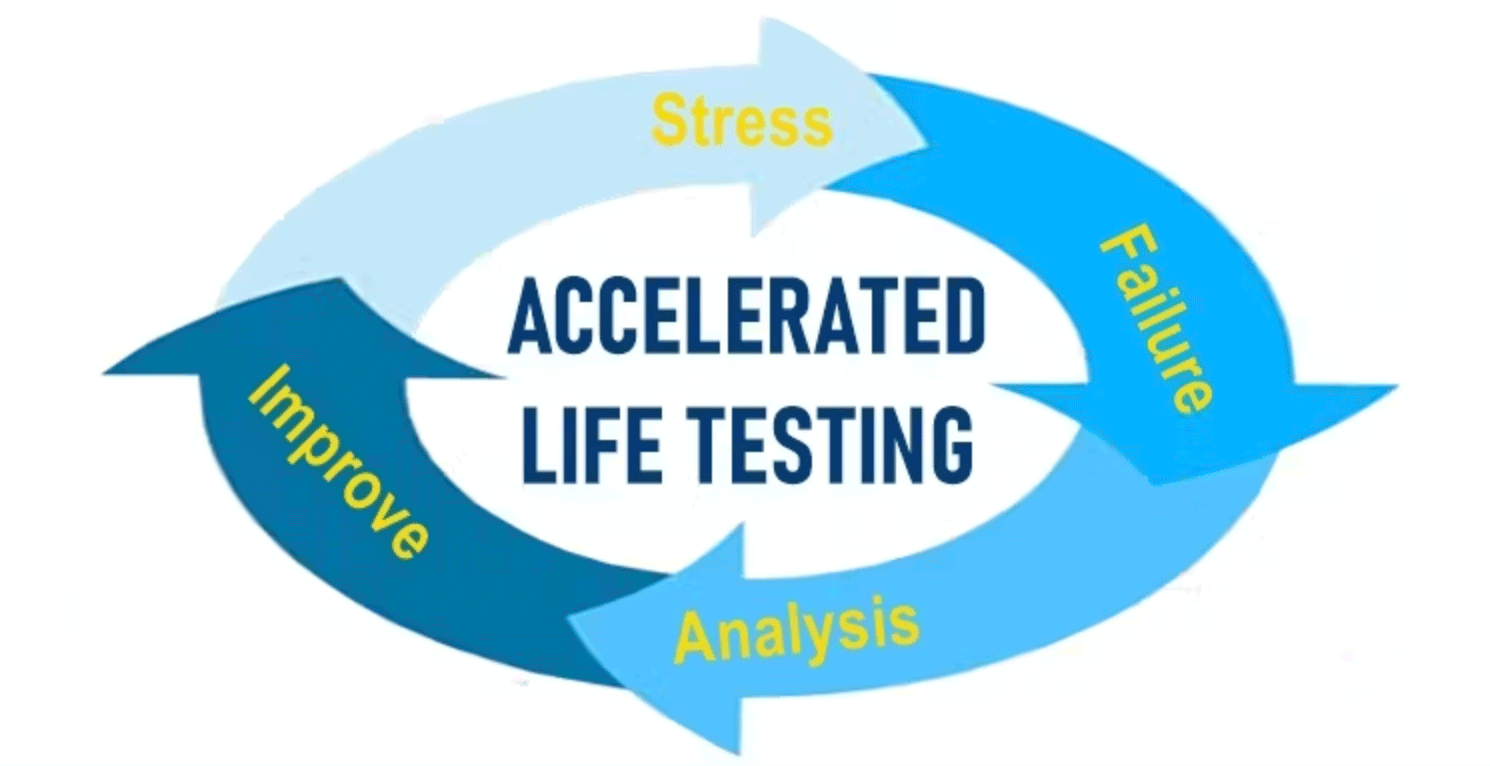

Why Accelerated Testing?

Business decisions, whether in management or engineering, rely heavily on test results. In today's competitive market, rapid decision-making is essential. Accelerated life testing offers a time-efficient method to obtain test results. It allows companies to assess a product’s reliability and durability within a shorter timeframe, facilitating quicker responses to market demands.

Types of Reliability Testing

Reliability testing can be categorised based on product maturity, potential failure modes, and product complexity. Common types include:

- Component Level Testing: Evaluates the reliability of individual components.

- System Level Testing: Assesses the overall reliability of an entire system or product.

- Degradation Testing: Monitors the product’s performance over time.

- Step Stress Testing: Gradually increases stress levels to identify failure thresholds.

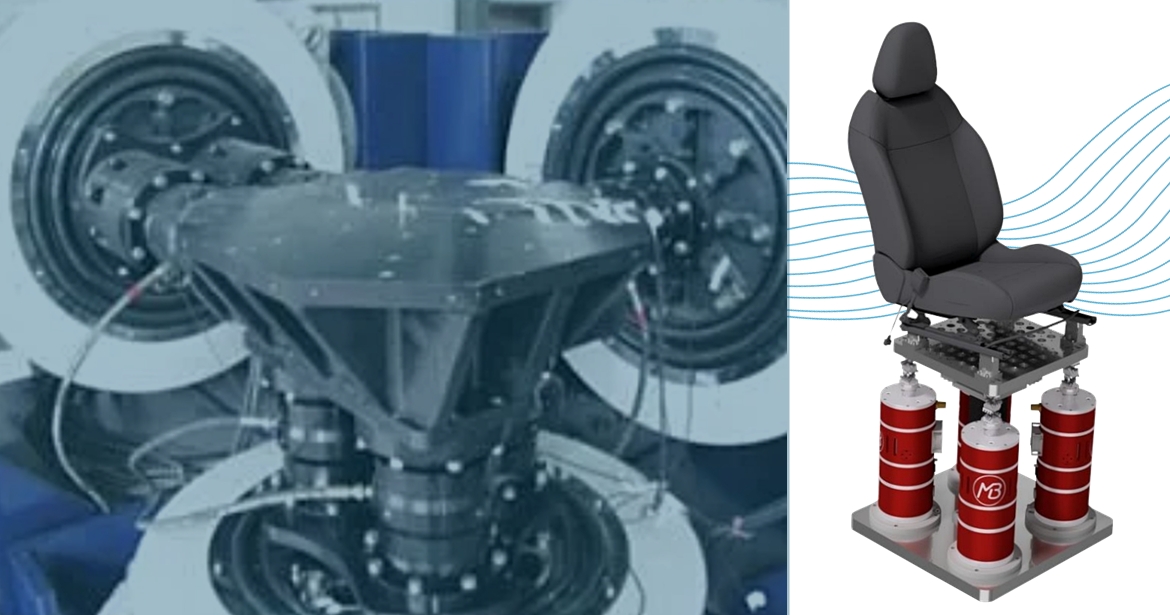

- Highly Accelerated Life Test (HALT): Exposes products to extreme conditions to uncover vulnerabilities.

- Failure Mode Intensification Test (FMIT): Reproduces and intensifies specific failure modes for analysis.

Ways to Accelerate Reliability Testing

Accelerating reliability testing involves various methods, each aiding different management and engineering decisions. Common acceleration tests include:

- Temperature Testing: Alters temperature conditions to assess the product’s behaviour under thermal stress.

- Voltage Testing: Varies voltage levels to examine the product’s performance and electrical reliability.

- Humidity Testing: Changes humidity conditions to determine their impact on the product’s reliability.

- HALT (Highly Accelerated Life Test): Applies extreme conditions to shorten the time to failure and uncover weaknesses.

- HASA (Highly Accelerated Stress Audit): Subjects products to severe conditions to identify design and manufacturing defects.

- FMIT (Failure Mode Intensification Test): Replicates and intensifies specific failure modes to better understand their causes.

Physical Models in Accelerated Testing

Physical models are used in accelerated testing to calculate acceleration factors and predict reliability under actual usage conditions. Common models include:

- Arrhenius Model: Relates temperature to the rate of chemical reactions, predicting product performance under different temperature conditions.

- Eyring Model: Provides insights into how stress factors, such as temperature, affect the time to failure.

- Inverse Power Law: Calculates acceleration factors and predicts product reliability under varying stress levels.

Highly Accelerated Life Test (HALT)

HALT is a vital concept in accelerated testing, designed to significantly shorten the time to failure. Key benefits of HALT include:

- Product Characterisation: Identifies operational and destructive limits.

- Supplier Qualification: Ensures the reliability of products from suppliers.

- Failure Mode Detection: Reveals potential failure modes during manufacturing.

- Field Failure Reproduction: Replicates field failure modes in a controlled environment.

- Understanding Physics of Failure: Provides insights into the root causes of failures.

Failure Mechanism Intensification Test (FMIT)

FMIT is an integral part of accelerated testing aimed at intensifying specific failure mechanisms. Defining test profiles for HALT and FMIT involves careful consideration of FMEA (Failure Modes and Effects Analysis) and FTA (Fault Tree Analysis). Effective HALT and FMIT testing can lead to significant time and cost savings.

By employing these advanced testing methods, businesses can enhance product reliability, mitigate risks, and respond more effectively to market demands.

Visit the CentraTEQ Ltd website for more information on Accelerated Life Testing: Reducing Risk and Improving Reliability