Mastering Automotive Quality: The Role of Buzz, Squeak, & Rattle (BSR) Testing Systems

When it comes to vehicle quality, noise is a critical factor that can significantly impact consumer satisfaction. Buzz, squeak, and rattle (BSR) noises, often perceived as minor issues, can leave a lasting negative impression, making even the most luxurious vehicle feel substandard. These unwanted sounds, caused by vibrations or poorly secured components, are a key focus for automotive manufacturers aiming to enhance the driving experience.

To address these challenges, manufacturers turn to Buzz, Squeak, and Rattle test systems, such as those provided by MB Dynamics, available in the UK through CentraTEQ.

What is Buzz, Squeak, and Rattle (BSR) Testing?

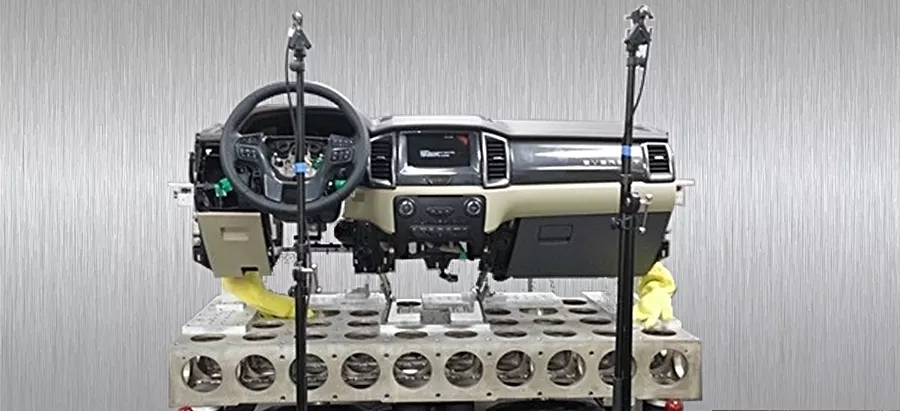

BSR testing is a quality assurance process in the automotive industry designed to detect and eliminate unwanted noises in vehicles. These sounds can originate from various parts of the car, including the dashboard, doors, seats, and trim panels.

- Buzz: A rapid, vibrating noise caused by loose or unsecured parts.

- Squeak: A high-pitched noise resulting from friction between two surfaces rubbing together.

- Rattle: A knocking or clattering sound, often due to misaligned or loose components.

These noises often become more noticeable as vehicles age, so manufacturers aim to address BSR issues early in the design, production, and assembly stages.

The Importance of BSR Testing in Automotive Design

-

Customer Satisfaction: Consumers expect a quiet, refined driving experience. Unpleasant noises can lead to dissatisfaction, complaints, and damage to a brand’s reputation.

-

Durability and Longevity: BSR testing ensures that components are securely fitted and durable, preventing structural failures that could arise from loose parts.

-

Cost-Effectiveness: Detecting BSR issues during the design phase is significantly more cost-effective than addressing them post-production, where warranty claims and recalls can be costly.

MB Dynamics: Leaders in BSR Testing Technology

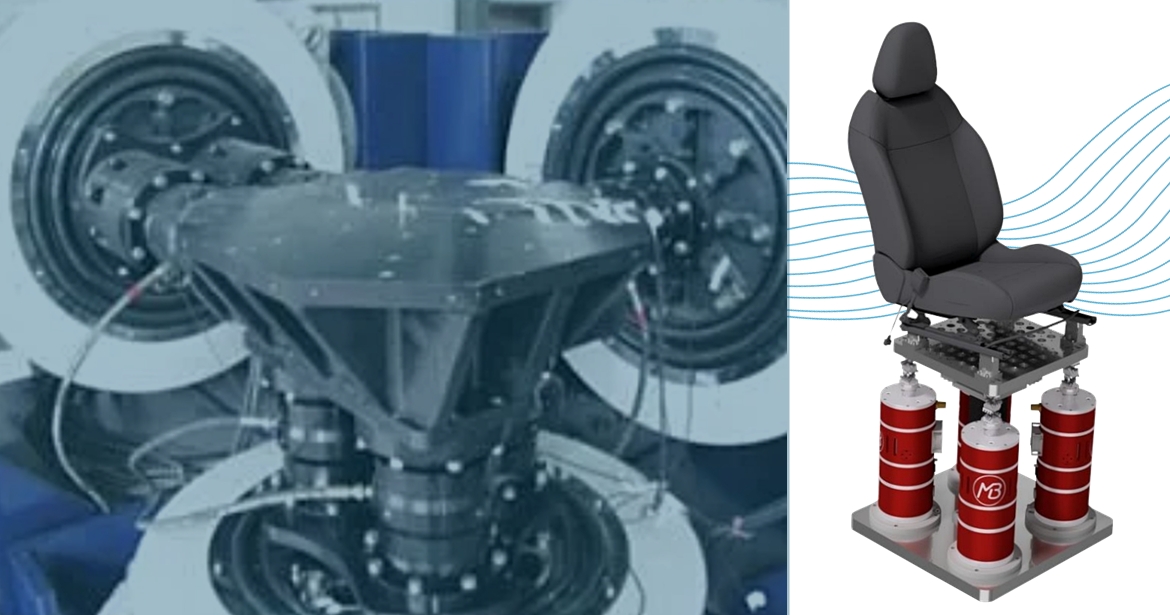

MB Dynamics is a global leader in vibration testing and sound measurement, offering cutting-edge BSR test systems designed to simulate real-world driving conditions. These systems allow manufacturers to identify and resolve BSR issues before vehicles are delivered to customers.

MB Dynamics’ BSR solutions are engineered to meet the exacting demands of the automotive industry, providing precise, reliable tools for tackling noise-related challenges.

MB Dynamics BSR Testing Systems Available at CentraTEQ

In the UK, manufacturers can access MB Dynamics’ state-of-the-art BSR testing systems through CentraTEQ, the exclusive distributor. With a wealth of experience in vibration and sound testing, CentraTEQ provides comprehensive support to help manufacturers integrate MB Dynamics’ solutions into their quality control processes.

CentraTEQ offers:

- Consultation and System Design: Tailored solutions to meet specific testing requirements.

- Installation and Training: Ensuring teams can operate systems efficiently and effectively.

- Ongoing Support and Maintenance: Keeping BSR systems running at optimal performance.

MB Dynamics’ BSR systems include precise measurement tools, customisable test benches, and low-noise shaker systems, making them some of the most advanced and comprehensive solutions for addressing BSR noise challenges.

Invest in Noise-Free Excellence

By prioritising BSR testing, automotive manufacturers can deliver vehicles that meet consumer expectations for quality, refinement, and durability. With MB Dynamics and CentraTEQ, UK manufacturers have access to world-class tools to eliminate unwanted noises and ensure a superior driving experience.

Visit the CentraTEQ Ltd website for more information on Mastering Automotive Quality: The Role of Buzz, Squeak, & Rattle (BSR) Testing Systems