Reshoring: Why Now Is Prime Time For Manufacturers To Bring Production Back To The UK

21-02-2023

The global pandemic had far-reaching effects for manufacturing businesses, not just in the UK, but worldwide. Supply chains proved to be more fragile than had been judged, particularly for businesses obtaining services, materials, or parts from the Far East.

With transit times from China to the UK taking on average, 30 days, and shipping costs doubling due to Low Sulphur Regulations introduced in 2020, many manufacturing businesses have started to consider whether it would be prudent to bring production back home.

Shortening Supply Chains By Reshoring

While some British manufacturing companies, in the wake of Covid-19, were considering the benefits of near-shoring to north and east African countries, such as Egypt, Ghana, and Morocco, war in Ukraine has forced a rethink as to whether this solution will shorten supply chains sufficiently.

The economic repercussions of the pandemic were still rippling through global markets when Putin ordered his troops into Ukraine, leading to major economic shocks, a shortage of some metals, and soaring fuel prices.

Bringing production back to the UK offers tantalising benefits, including:

Tighter supply chains: reshoring alleviates many of the unknowns of supply chains, plugs gaps that can cause delays across the supply chain ecosystem, and gives manufacturers greater control and capacity to make informed decisions to overcome bottlenecks and shortages.

A stronger economy: while offshoring generates jobs in other countries, many of which are often poorly paid, reshoring provides much-needed employment in UK communities. Actively supporting local causes promotes a business’s social responsibility and adds value to the economic outlook, locally and nationally.

Shorter lead times: the greater the distance between a manufacturer and a customer, the longer the lead times. Delays are caused by many factors which are often unpredictable: border inspections, political upheaval, and extreme weather can all lengthen shipping time and increase costs. Reshoring, especially to a country as compact as the UK, removes many of the barriers and shortens lead times, contributing to enhanced brand perception.

How Hone-All Can Support Your Business’s Reshoring Strategy

When you need a part to be made to a high standard, it makes sense to opt for reshoring.

The UK has a long history of manufacturing prowess and is well-placed to support manufacturing businesses in their drive for greater efficiency and competitiveness.

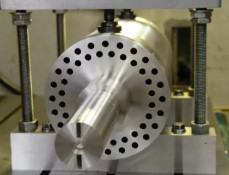

With extensive experience of delivering outstanding results for UK manufacturers in a range of industries, Hone-All’s end-to-end precision engineering service can make reshoring a cheaper and quicker solution. By choosing Hone-All as your engineering partner, you will benefit from:

Faster turnaround, with our dedicated engineers working hard to meet your project’s timescales.

No frustrating delays waiting for raw materials or finished products to arrive from overseas locations. We have complete control over our supply chains, procurement, and lead times.

Exceptional quality standards that comply with BS ISO 9001 and EN 9100.

Greater cost-efficiency, with lower overheads and shipping charges.

A guarantee that all work will be completed in our Bedfordshire manufacturing facility, with no outsourcing to third party businesses – unless you specifically request us to outsource something we cannot do in house such as material treatments etc.

At Hone-All, we are also advocates for a cross-industry, Government-backed taskforce to assess the resilience of the UK’s supply chains and create a positive plan of action to protect the economy from economic, political, and social disruption. By acting now to strengthen the case for UK businesses to reshore their manufacturing requirements, we believe that the country will be better protected and more resilient against global uncertainties in future.

Contact Us To Find Out More

If you would like to strengthen your supply chain, reduce your costs, improve lead times, and guarantee exceptional quality, please get in touch with Hone-All today on 01525 370666.