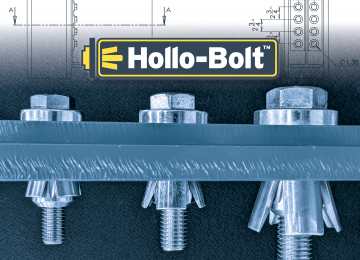

Hollo-Bolt: The ONLY highly approved blind bolt for structural steel

Since its launch in 1995, Lindapter’s Hollo-Bolt has transformed the way structural steel connections are made. As the industry’s leading blind fastener, Hollo-Bolt provides a reliable, efficient, and aesthetically pleasing solution for connecting Hollow Structural Sections (HSS). Its quick installation, superior performance, and international certifications make it the go-to choice for safety-critical applications.

Why Choose Hollo-Bolt?

The key advantage of Hollo-Bolt lies in its ability to create secure connections with access to only one side of the steel. This blind connection capability simplifies complex projects, reduces labour costs, and speeds up installation. Unlike traditional methods such as welding or through-bolting, Hollo-Bolt offers a cost-effective and safe alternative.

Available in a variety of head types and corrosion-resistant finishes, Hollo-Bolt is suitable for diverse applications, from high-rise façades to offshore installations. Options include:

- Hexagonal Head: Ideal for standard applications.

- Countersunk and Flush Fit: Low-profile options for architectural projects requiring a sleek aesthetic.

Unmatched Performance and Certifications

Hollo-Bolt stands out as the only blind bolt with multiple global approvals, including:

- CE Marking and UKCA Certification.

- ICC-ES Approval for seismic applications.

- Fire-rated to ASTM E-119, meeting strict fire safety regulations.

The High Clamping Force (HCF) variant delivers three times the clamping force of standard Hollo-Bolts, making it suitable for demanding structural connections in safety-critical environments, including regions prone to seismic activity.

Comparison with Alternative Methods

Hollo-Bolt surpasses traditional connection methods such as welding, brackets, or cutting access holes. Welding requires specialist labour, hot work permits, and poses risks like distortion or damage to thin-walled sections. By contrast, Hollo-Bolt eliminates these issues, offering:

- Safe, easy installation.

- Superior resistance to shear and tension forces.

- No need for hot work permits or specialist tools.

Simple Installation

Installing Hollo-Bolt is straightforward. Simply insert the fastener into pre-drilled holes and tighten it with a standard torque wrench. The HCF variant features a patented mechanism that enhances clamping force, ensuring a secure, high-strength connection without additional steps or equipment.

Global Recognition and Project Applications

Hollo-Bolt is trusted worldwide and has been used in numerous high-profile projects.

Case Study: ITER Nuclear Fusion Project

The ITER nuclear fusion project in Cadarache, France, the largest of its kind globally, demonstrates the capabilities of Hollo-Bolt. Designed to meet seismic safety standards outlined by the International Atomic Energy Agency (IAEA), Hollo-Bolt was chosen for its ICC-ES seismic approval, CE marking, and TÜV certification.

In this project:

- 20 mm hot-dip galvanised Hollo-Bolts were used to connect large structural beams.

- 10 mm stainless steel Hollo-Bolts secured smaller pipe brackets.

- Installation involved inserting the bolts into pre-drilled holes and tightening them to the specified torque, avoiding the need for welding or through-bolting.

The use of Hollo-Bolts reduced installation time and adhered to stringent safety standards, ensuring the project remained on schedule. The ITER reactor is expected to be operational by 2025, with full-scale fusion experiments planned for 2035.

Corrosion Resistance and Custom Solutions

Lindapter offers Hollo-Bolt in several finishes, including:

- Hot-Dip Galvanised: Ideal for industrial and coastal environments.

- Sheraplex Coated: Provides enhanced protection against corrosion.

- Stainless Steel: Suitable for highly corrosive environments.

For unique project requirements, Lindapter’s Engineered Solutions team can design customised Hollo-Bolts, tailored to specific applications.

Key Benefits of Hollo-Bolt

- Fast installation with access needed from just one side.

- No specialist tools, hot work permits, or fire watches required.

- High corrosion resistance for durability in harsh environments.

- Aesthetic head options for architectural finishes.

Combining ease of installation, exceptional performance, and global recognition, Lindapter’s Hollo-Bolt sets the standard for structural steel connections. Its versatility, superior safety features, and sleek design make it the ideal choice for engineers and architects seeking a reliable and visually appealing fastening solution.

Visit the Lindapter International website for more information on Hollo-Bolt: The ONLY highly approved blind bolt for structural steel