Finite Element Analysis (FEA) Service

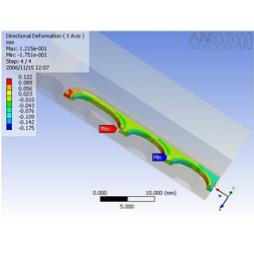

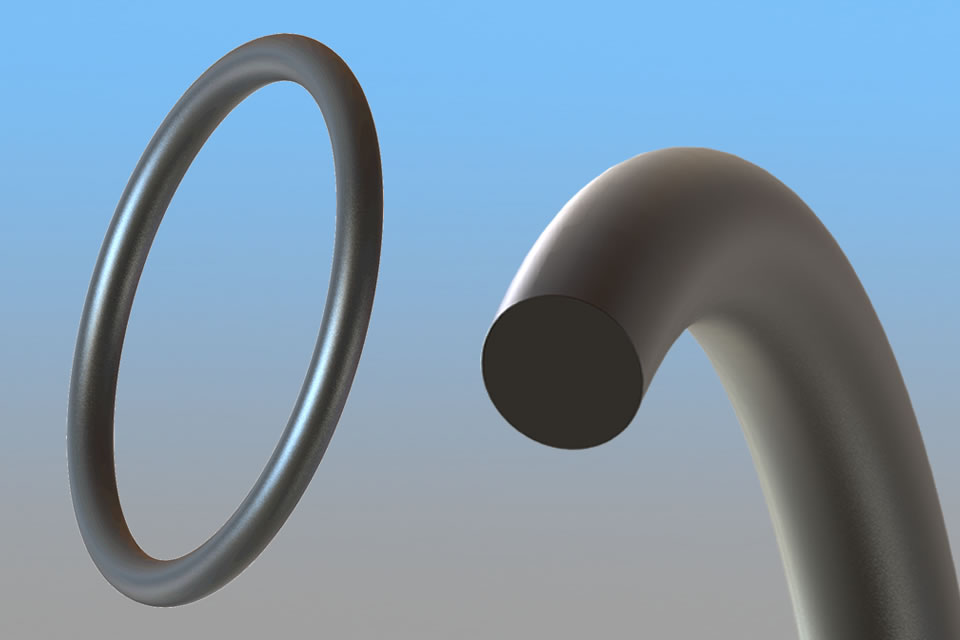

Finite Element Analysis (FEA) is a computer simulation technique used to predict contact forces, deformation and stress levels within elastomer components. In order to maximise the accuracy of modelling, PPE engineers generate temperature specific material models for specific applications.By lowering stresses within an elastomer we can reduce the effect of stress induced chemical attack and therefore prolong the life of a component in application.Being able to draw from a large range of in-house compounds and a comprehensive supply chain, our design team are able to recommend the best materials for your application, either using solely elastomers, or augmenting them with metals or thermoplastics such as PTFE or PEEK?.FEA helps the designer to address complex seal geometries, where assessing the sealing force is difficult, both intuitively and to calculate manually.The use of such predictive behavioural programmes can be highly beneficial across a wide range of applications for elastomer seals.Visit the Precision Polymer Engineering Ltd website for more information on Finite Element Analysis (FEA) Service