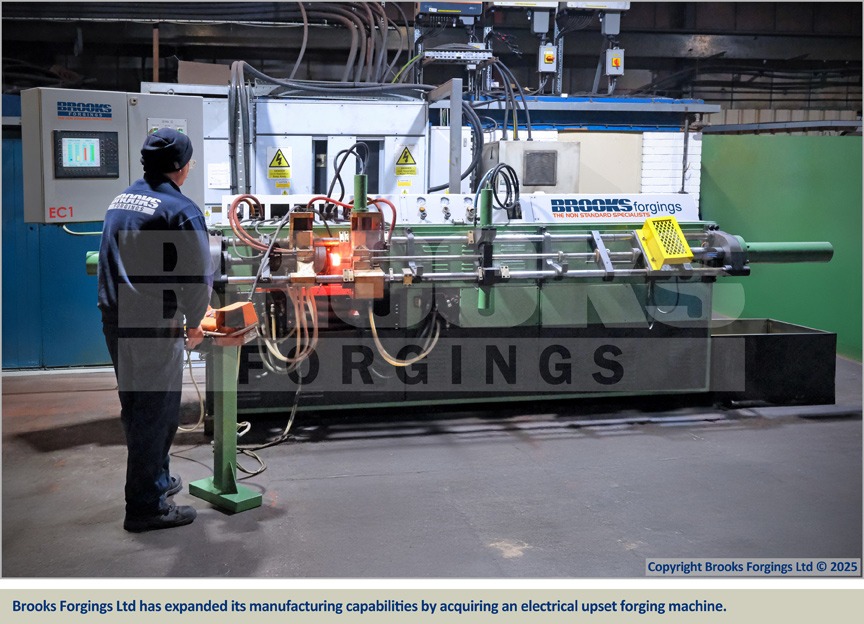

Electrical Upset Forging Machine Installed Further Increasing Our Manufacturing Capability

Brooks Forgings Ltd has expanded its capabilities with the acquisition of an electrical upset forging machine, significantly increasing throughput at its Lye, Stourbridge site. Fully refurbished, commissioned and now operational, the machine was purchased from the Tinsley Bridge Group—the last of their remaining upset forging assets—previously used to produce torsion and anti-roll bars, a field in which Brooks Forgings is already a recognised UK leader.

Electrical upset forging combines electrical resistance heating with hydraulic pressure to gather a large mass of material from a single heat, typically at the end of a comparatively small-diameter bar. The process accommodates starting stock up to 60 mm diameter and is suitable for steels, stainless steels and other high-conductivity alloys.

Compared with conventional upset forging, this method requires less tooling and offers shorter set-up times, reducing production costs. It also lowers the carbon footprint per component by using only the energy required for each cycle, supplemented by the company’s solar power reserves, rather than relying on continuously fired oil or gas furnaces.

The machine’s integrated computer control allows operators to store and recall precise forging parameters, building a library by material, length and diameter. This ensures full repeatability and enables less experienced operators to run the process with minimal training. For higher-volume programmes, the system is readily adaptable to robotic handling for fully automated production with minimal operator input.

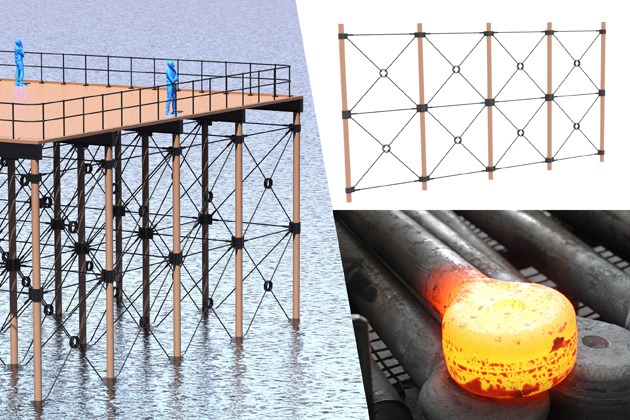

Electrical upset forging is well suited to components such as torsion bars, transmission shafts, flanged shafts, thermowells, eye bolts, headed bolts and tie rods. This strategic investment underlines Brooks Forgings’ commitment to being the most versatile manufacturer in the UK.

Visit the Brooks Forgings Ltd website for more information on Electrical Upset Forging Machine Installed Further Increasing Our Manufacturing Capability