Understanding Lindapter Girder Clamps: An Introduction

In the world of construction and engineering, the efficient connection of structural elements is crucial for ensuring safety, stability, and ease of assembly. Lindapter Girder Clamps, often referred to as beam clamps, exemplify innovation in this field. This introductory guide explores the functionality, advantages, and diverse range of products offered by Lindapter.

What are Lindapter Girder Clamps?

Lindapter pioneered a mechanical steel connector system designed to securely connect steel beams, girders, and other structural components without the need for welding or drilling. This innovative solution provides a versatile alternative to traditional connection methods, such as bolting or welding, enabling rapid and efficient assembly of structures across various industries, including construction, infrastructure, and industrial applications.

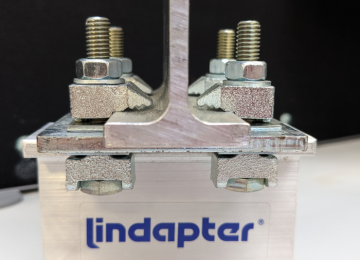

How Do They Work?

The operation of Lindapter Girder Clamps is simple yet highly effective. These clamps feature a unique design that allows the nose of the clamp to grip onto the flanges of steel beams or girders. This secure grip is achieved by tightening bolts, which compress the jaws against the beam flanges, creating a stable and reliable connection.

One of the standout advantages of Lindapter Girder Clamps is their adjustability. Unlike fixed connection methods such as welding, Lindapter clamps allow for precise alignment and adjustment during installation, accommodating variations in beam dimensions or alignment errors.

Advantages of Lindapter Girder Clamps

-

No Welding or Drilling Required: Lindapter clamps eliminate the need for hot work permits, specialised welding equipment, and the associated safety concerns and costs.

-

Time and Cost Savings: By avoiding the time-consuming processes of welding or drilling, Lindapter Girder Clamps contribute to significant time and cost savings during construction or installation.

-

Adjustability: The ability to adjust and realign connections during installation simplifies the assembly process and ensures precise alignment of structural components.

-

Non-Destructive Installation: Lindapter clamps can be installed without damaging the beam's protective coatings or structural integrity, thereby preserving the structure's overall quality.

-

Versatility: Lindapter offers a wide range of clamping solutions designed to suit various beam sizes, profiles, and applications, providing flexibility for diverse construction projects.

Lindapter's Catalogue

Lindapter provides a comprehensive selection of Girder Clamps tailored to meet the specific needs of different industries and applications. Some key products include:

-

Type A Clamps: Designed for horizontal flanges, these clamps are used to resist moderate tensile loading.

-

Type B Clamps: The flat-top version of Lindapter’s standard clamp, suitable for moderate tensile loading.

-

Type AAF Clamps: An adjustable High Slip Resistance (HSR) clamp, easy to install and provides high load capacities even in low-temperature environments, with hot-dip galvanised corrosion protection.

-

Type AF Clamps: A heavy-duty clamp offering the highest load capacities of all Lindapter’s High Slip Resistance clamps.

-

Type CF Clamps: Hooks over the flanges of beams, angles, and channels to connect steel sections that do not face each other, such as connecting horizontal beams with vertical columns.

-

Type LR Clamps: A versatile, self-adjusting clamp designed to accommodate a range of flange thicknesses.

-

Type D2 Clamps: An adjustable clamp with a Setscrew Tail that can be adapted to fit various flange thicknesses.

-

Type LS Clamps: Offering excellent corrosion resistance, this stainless steel clamp self-adjusts to suit different flange thicknesses.

-

Type F9 Clamps: A flange clamp for connecting parallel-running steel sections with flanges of the same width. Can be used with bolts or threaded rod.

-

Type FC – Flush Clamp: A complete connection system that adjusts to fit various beam types. This pre-configured assembly requires no location plate and is ready for assembly ‘out of the box’.

-

Stainless Steel Clamps: Ideal for applications requiring corrosion resistance or hygiene considerations, Lindapter’s Type LS stainless steel clamp is suitable for harsh environments.

Download our Girder Clamps Introduction Flyer to learn more.

Summary

Lindapter Girder Clamps represent a significant advancement in structural connection technology, offering a versatile, efficient, and cost-effective alternative to traditional methods. With their innovative design, adjustability, and extensive product range, Lindapter clamps have become indispensable tools for engineers and construction professionals worldwide, enabling the assembly of safe, stable, and durable structures across a variety of industries and applications.

Visit the Lindapter International website for more information on Understanding Lindapter Girder Clamps: An Introduction